Distribution Center – Lake City, FL

At a distribution facility in Lake City, Florida, Byers delivered the electrical buildout supporting an automated material-handling system—tying power, controls, communications, and safety devices into a clean, code-compliant backbone for conveyors and associated equipment. The engagement provided labor, materials, and equipment per bid documents to ensure reliable operation and maintainable layouts coordinated with other trades.

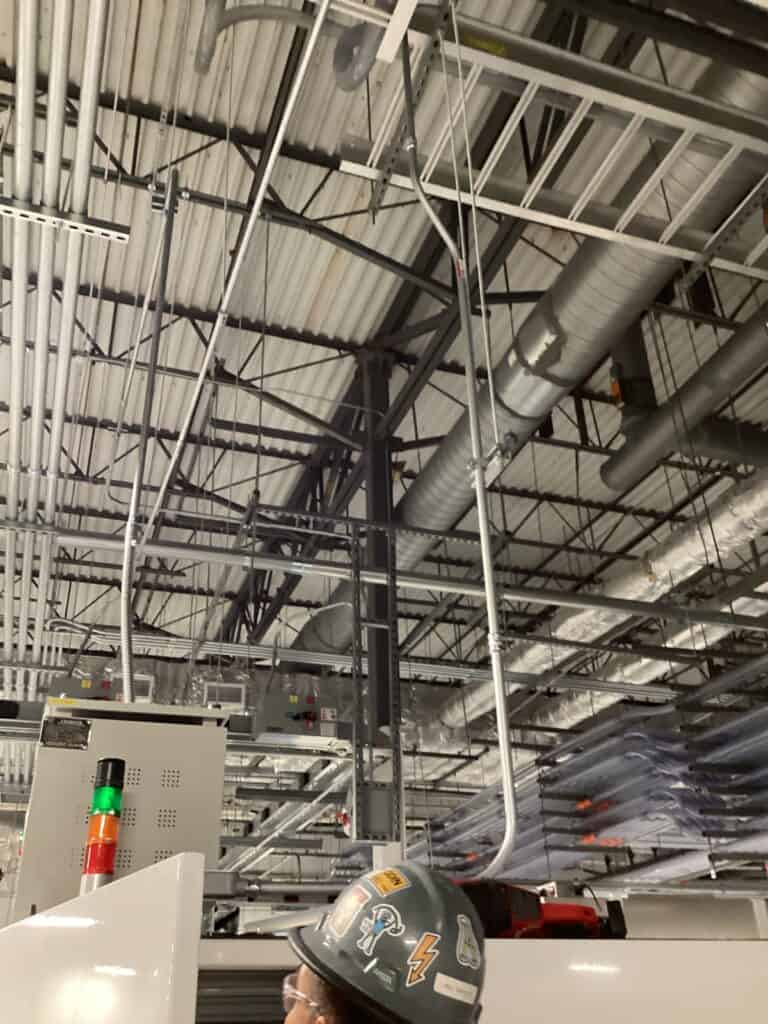

Scope included installing the bus system and bill-of-materials components; pulling feeder conductors from the aisle access panel (AAP) to the bus; routing cable from the AAP to the disconnect (with incoming power to the disconnect provided by others); mounting enclosures not factory-installed; furnishing and installing wire basket tray beneath conveyors (with the only overhead raceway from the AAP to the bus); installing customer-provided cables, then terminating and testing; providing, terminating, and testing all I/O cables per the I/O list; installing e-stops; mounting and aligning the barcode-scanner bracket; and setting the profile-check rack with its control box.

Execution followed the project drawings and standard conditions, with clear delineations to streamline commissioning: incoming power, certain outlets, MCP/PLC power, and specified brackets/racks/posts were by others; designated control wire and device cables were owner-supplied. Byers coordinated staging, safe rigging, precise mounting, and labeled terminations to support efficient testing, turnover, and long-term maintainability of the automated system.