Coffee Roasting Facility – Minden, NV

Byers proposed the complete process-electrical package to support a roasting plant upgrade, organized around a detailed milestone schedule with pre-bid activities, submittals, site mobilization, and area-by-area installation. The plan coordinates weekday work windows with a planned power outage to integrate new equipment safely and keep construction aligned with ongoing operations.

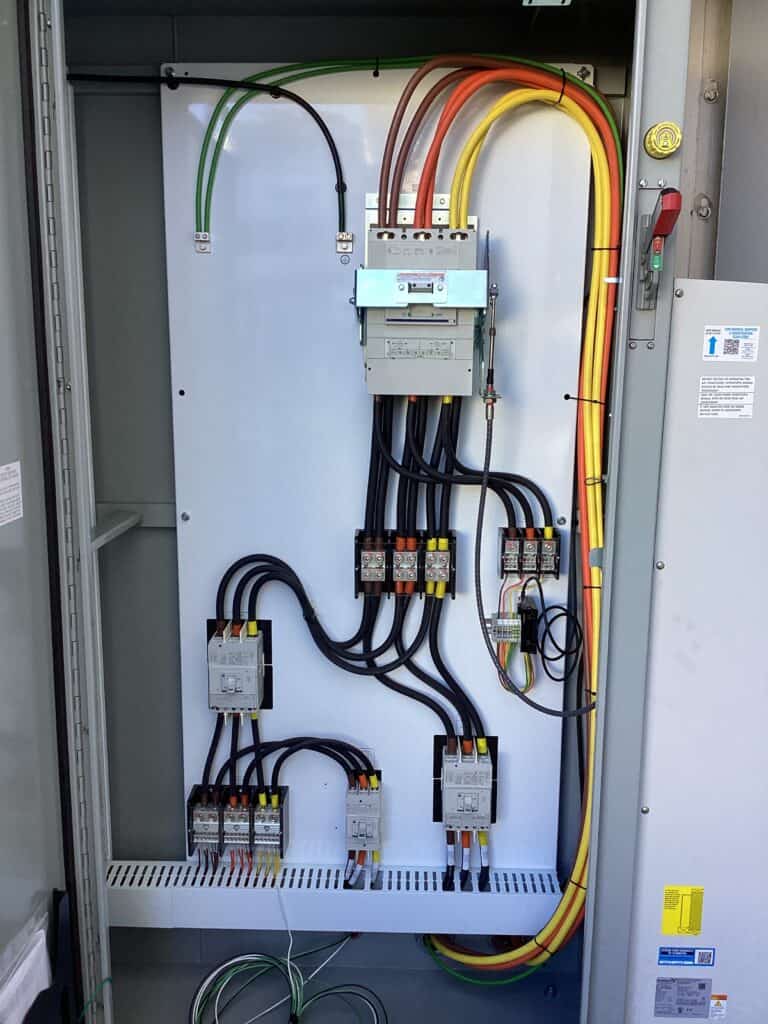

The scope centers on a new dust-collection system with associated HVAC rework (including VFD integration), demolition of legacy dust collection and spark detectors, start-up support, and new heat-trace power/branch circuits. Additive items include offloading/setting control panels, power and terminations for a sanitary process package, installation of spark-detection and divert-valve/pressure-transmitter devices, and additional HVAC VFD work—each defined in the base scope and alternates

Execution is sequenced to rig and set panels, complete pre-work ahead of equipment setting, and perform the bus-duct disconnect install during the scheduled outage, followed by installation and start-up for takeaway, hot-/cold-chaff, green-dust, and roasted-system areas. The plan concludes with demolition handoffs, punch-list closeout, arc-flash documentation, and final completion—supported by testing per specifications and standard safety/insurance qualifications.