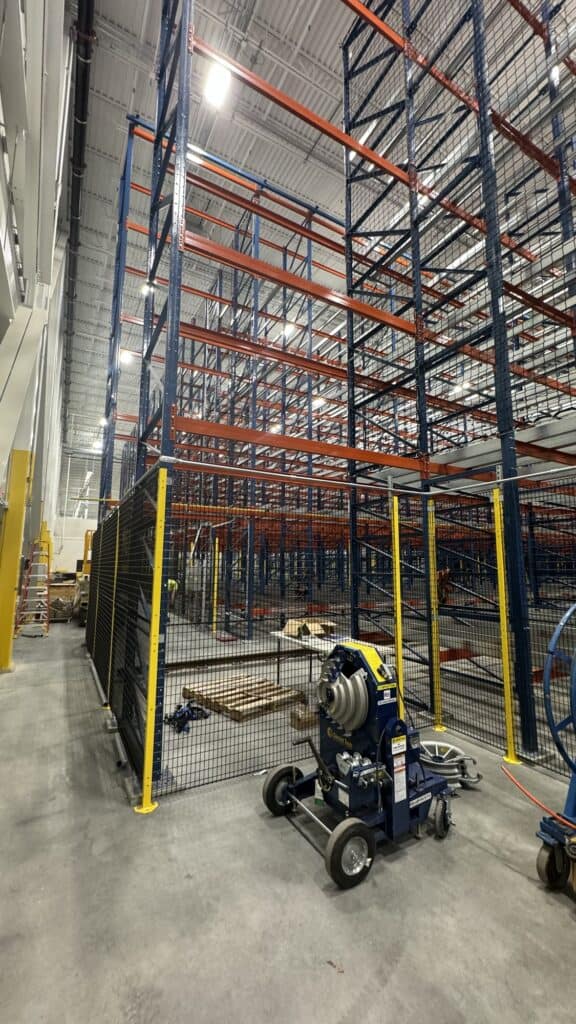

Automated Storage & Retrieval | Expansion – Phase 2 | Philadelphia, PA

At a distribution terminal, Byers delivered the electrical package for a Phase 2 expansion of an automated storage and retrieval system (AS/RS), tying new conveyors and machine sections into a clean, code-compliant backbone. The work plan covered labor, materials, equipment, QA/QC, safety, and project management, sequenced to regular weekday day shifts for safe coordination with parallel trades.

Scope included reconnecting machine-mounted wire basket tray across multiple conveyor sections; furnishing and installing new 12-inch basket tray with dividers and covers where required; installing two bus runs for the SRMs with rack-supported brackets; setting a new remote I/O panel, two SRM operator stations, one system display station, two aisle access panels with raceway/wiring from disconnects, and two tow-arm enclosures; placing MCP-05/-06/-07; installing six light-curtain enclosures and three BCS units; installing and wiring all related I/O; pulling three fiber runs (approx. 200′ each, final MCP locations TBD); and adding grounding raceways with bonding provisions suitable for UL-listed tray systems.

Execution emphasized precise mounting, labeled terminations, and safe interfaces at fencing, stands, and machines (including e-stops), with tray bonding, ground continuity, and device alignment verified during installation. The result is a maintainable electrical infrastructure that integrates new SRM aisles and conveyor equipment while streamlining commissioning and long-term operations