Beverage Bottling Facility – Billings, MT

For a beverage production facility’s Line 2 expansion, Byers delivered the turnkey electrical installation to support high-throughput bottling and packaging. The team coordinated layout, sequencing, and safety around active operations, establishing a clean, code-compliant backbone for power distribution, controls, networking, and device safety—ready to integrate with existing plant systems.

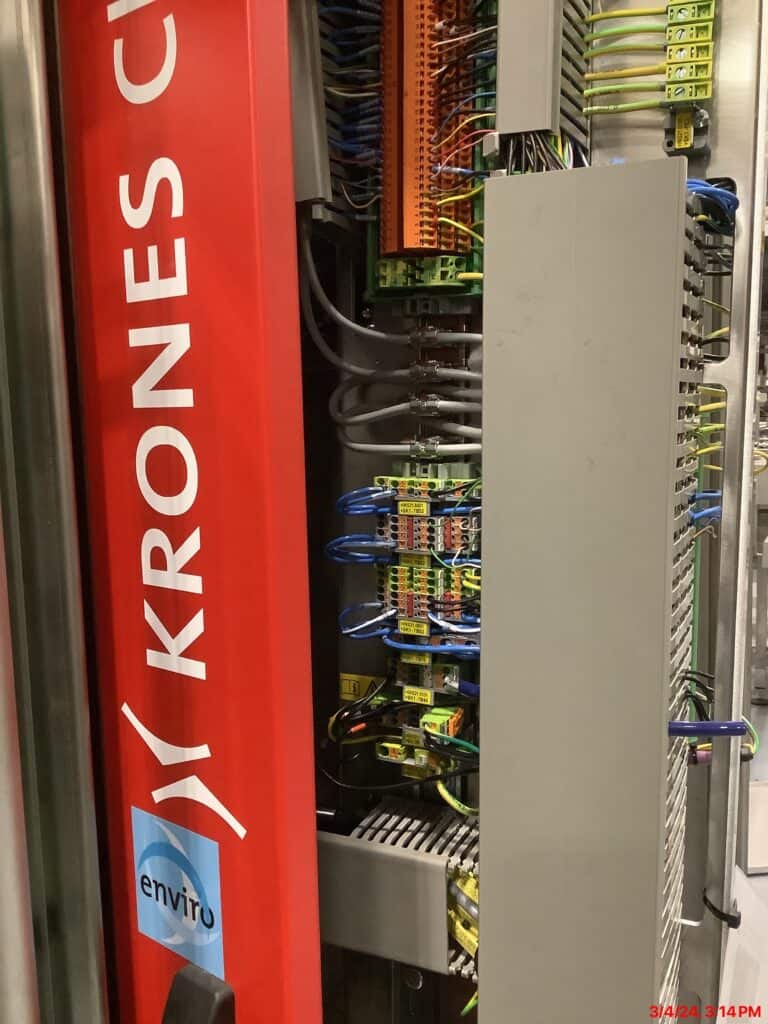

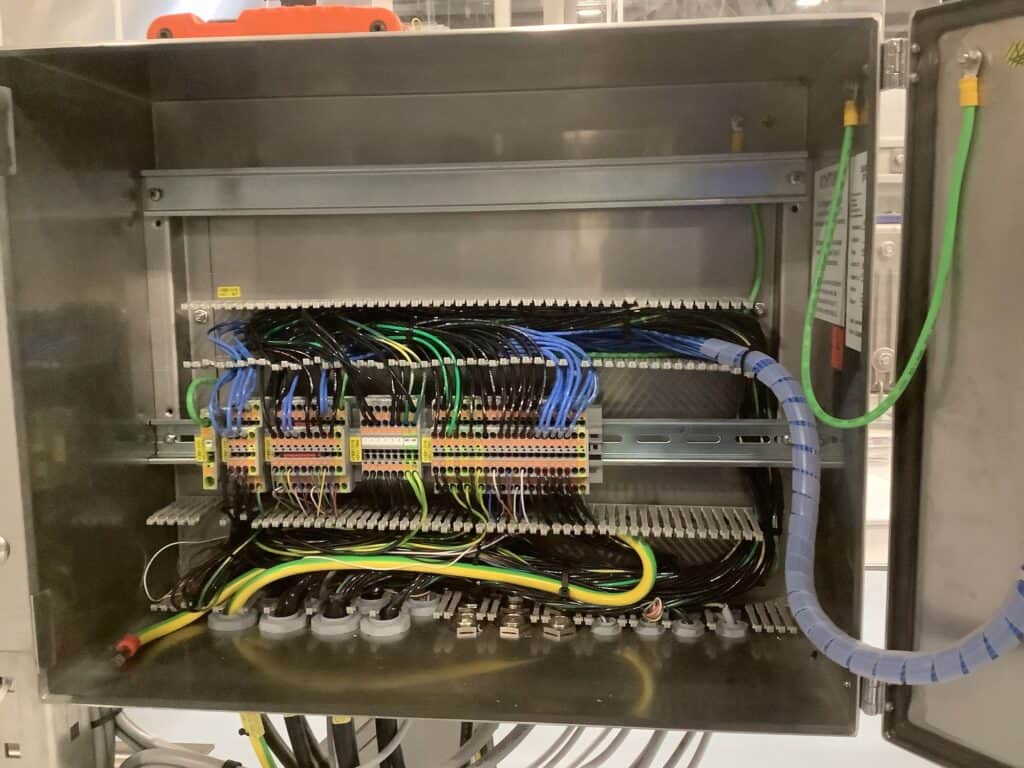

Scope included fabricating and installing cable-tray supports; setting and tying in control panels and local disconnects; routing feeders and branch circuits; installing overhead and conveyor tray; and pulling power, control, and network cabling from cabinets and junction boxes to all field devices. Byers completed terminations in panels and at the equipment, integrated e-stops and operator stations, and provided labeling and documentation to unify the line as a cohesive, maintainable system.

Execution emphasized disciplined staging, safe rigging, precise mounting, and clear separation of voltages for reliability and serviceability. The team supported start-up with I/O checks, device verification, and as-built updates—delivering an electrical installation that enables efficient commissioning, rapid troubleshooting, and long-term performance for the upgraded production line.