Beverage Bottling Facility – New Jersey

At a beverage bottling facility in New Jersey, Byers delivered the turnkey electrical installation for a new packaging line, coordinating layout, sequencing, and QA/QC to tie customer-supplied trays, wireway, and cabling into a clean, code-compliant backbone. Work planning targeted weekday/Saturday day shifts to maintain schedule and safe interfaces with parallel trades.

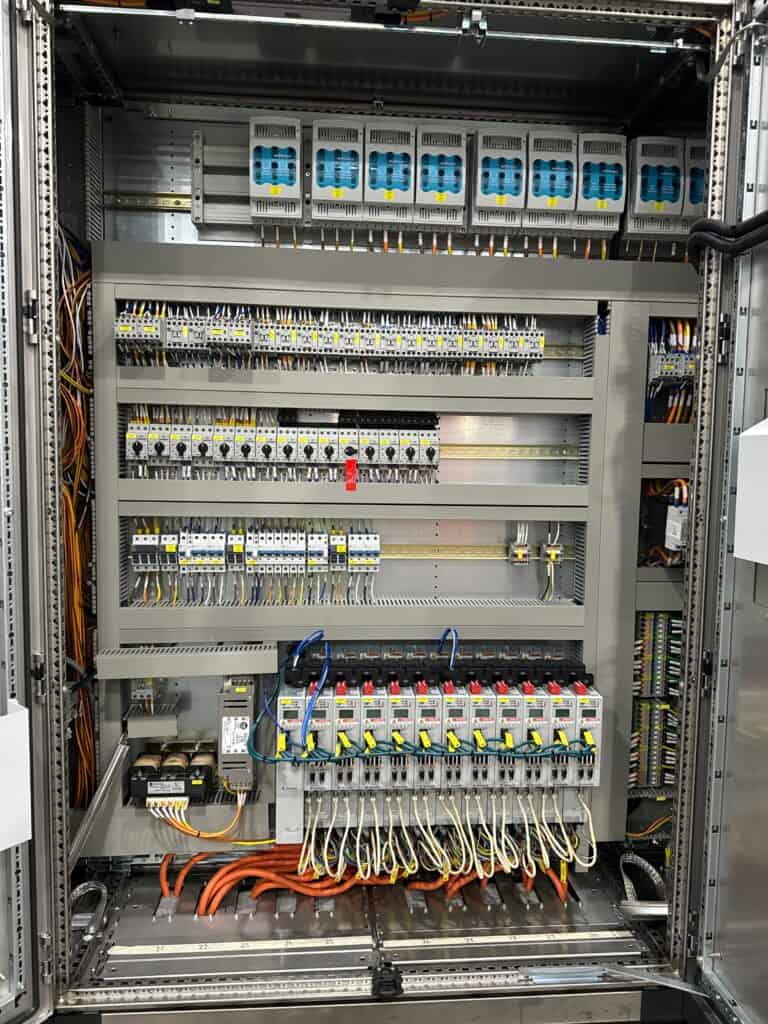

Scope included receiving and inventorying owner-furnished materials; installing overhead cable tray/wireway, fittings, and selected control panels; and setting field devices and controls across the line—disconnects, remote I/O panels, stop/start stations, beacon lights, horns, HMIs, reset stations, a spiral-conveyor control station, aligner sensors, and rail control stations. All device cabling (24 VDC and Cat6 where required) was routed to corresponding remote I/O, with device and panel terminations completed per the bid documents and revised scope.

Execution emphasized disciplined cable management, labeled terminations, and defined delineations: major distribution panels and all power/control/Ethernet cables furnished by others; tray supports by others where shown, with contractor-provided threaded-rod/Unistrut supports where specified. The plan included allowances for start-up and check-out hours to streamline commissioning and bring the upgraded line online efficiently.