Dust Collection & Ductwork Installation – Temple, TX

At a bottling facility in Temple, Texas, Byers proposed a fixed-rate program to install dust-collection systems in two production areas, providing equipment, materials, and labor for a clean, code-compliant installation. Work planning targets weekday 10-hour shifts to coordinate safely with other trades and maintain schedule.

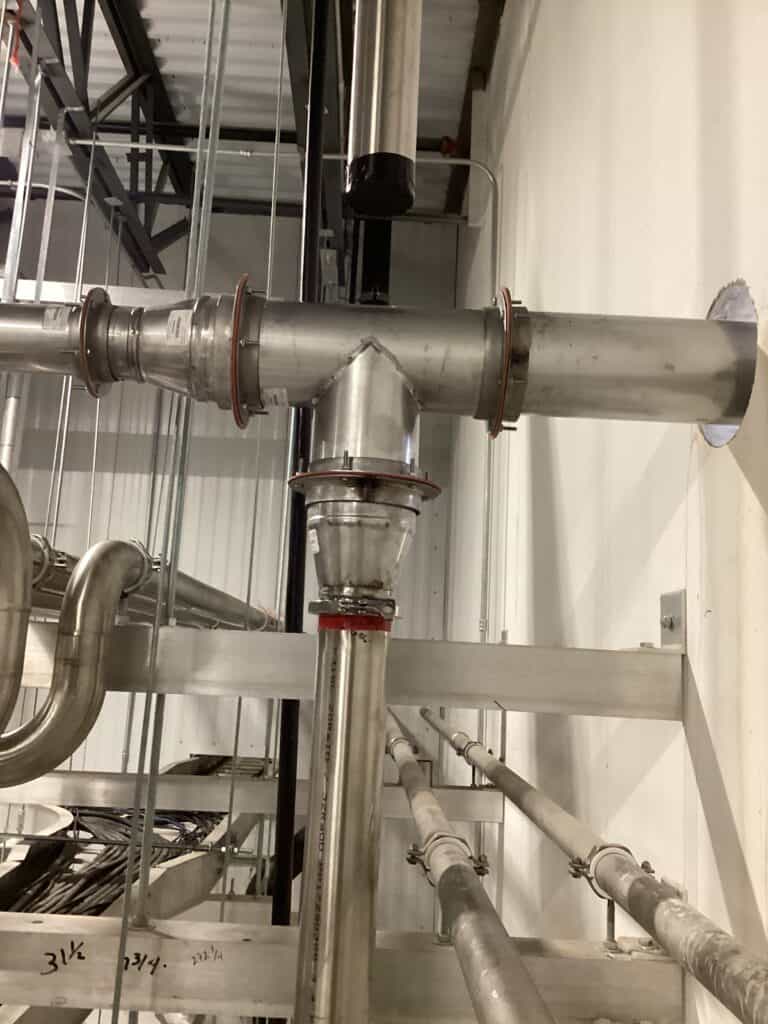

Scope includes unloading, unpacking, setting, and anchoring each dust collector; installing structural frames; rigging main bodies; and setting blowers, silencers, rotary-valve hoses, drum covers, filter cartridges, and sensors. Ductwork will be field-routed 6″ galvanized spiral—approximately 35′ in one area and 125′ in another—with 4″ drops picked up at the IMP ceiling into the 6″ trunk, blast gates at each branch, and all required hangers. A 1″ compressed-air line will be installed from within about 20′ of the wall to each collector.

Execution notes and delineations: dust collectors are owner-supplied; Byers’ package includes all labor, materials, and equipment needed to complete the listed scope; 4″ drops through the IMP ceiling are by others; and dumpsters/portable restrooms are excluded. The installation emphasizes safe rigging, precise anchorage, and efficient tie-ins to deliver a maintainable system ready for commissioning.