Glass Manufacturing Facility

Byers Industrial enhanced high-voltage reliability and maintainability at a glass manufacturing facility by adding sectionalizing capability to the plant’s overhead service. The solution introduced dedicated isolation points around the site so crews can de-energize specific segments for safe work while keeping adjacent systems available to operations.

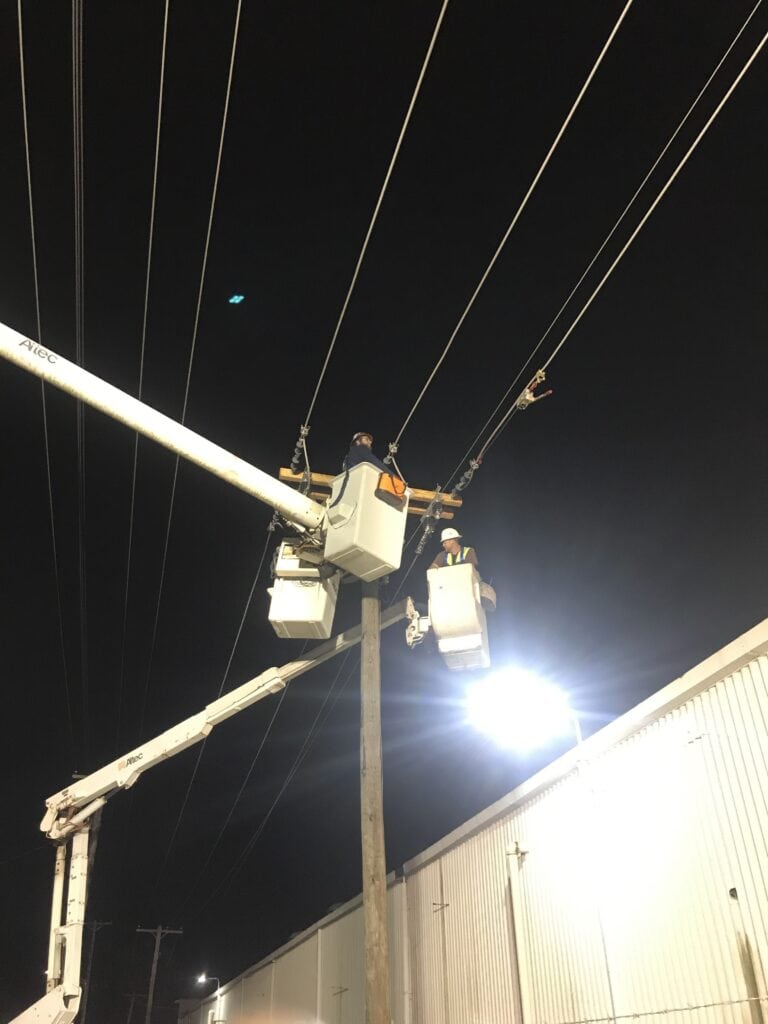

Scope included installing two sets of three 600-amp, 15 kV solid-blade, crossarm-mounted switches on the existing 13,200-volt overhead distribution. Work was executed during a scheduled shutdown: the team safely grounded the 477 ACSR conductors, used come-alongs to create slack, performed controlled cuts, and installed dead-end grips, polymer dead-end insulators, and related pole-line hardware to integrate the new switching assemblies.

The upgraded configuration provides clear isolation points for faster lockout/tagout, safer maintenance, and reduced downtime. With robust hardware and thoughtful layout, the plant gains flexible switching, improved fault response, and a durable platform for future expansion of the high-voltage system.