Engineered for Demanding Environments.

Our mechanical division provides equipment installations, process and stainless steel pipe welding using Orbital Welding Technologies for both Food Grade and Pharmaceutical Grade applications. We provide in-plant maintenance and repair of equipment and facilities, along with being available 24 hours a day to keep you and your business up and running when emergencies arise.

Mechanical Services Include:

Mechanical Services Include:

- Certified Welders

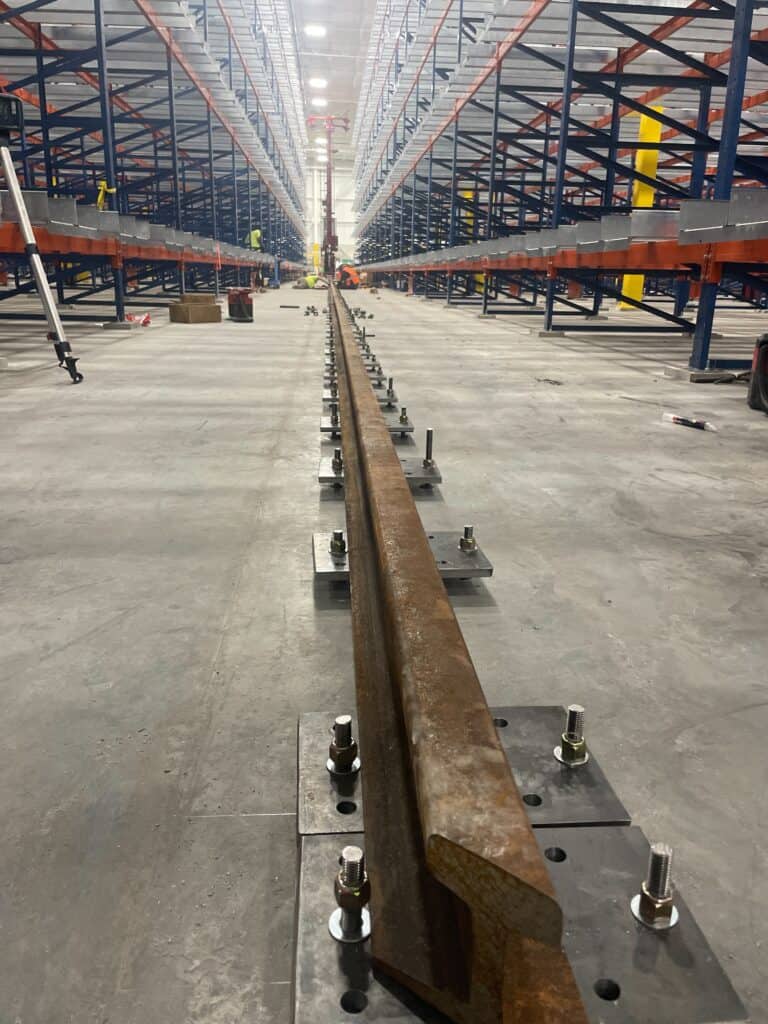

- Conveyor Systems

- CNC Plasma Cutting

- Custom Fabrication

- Demolition and Rebuild

- Equipment Setting

- Millwright Crews

- Packaging and Distribution Lines

- Plumbing/Pipe Fitting

- Process and Stainless Pipe Welding and Installations

- Rigging

- Sanitary Welding

- Certified Welders

- Conveyor Systems

- Carpentry

- CNC Plasma Cutting

- Custom Fabrication

- Demolition and Rebuild

- Equipment Setting

- Millwright Crews

- Plumbing/Pipe Fitting

- Packaging and Distribution Lines

- Process and Stainless Pipe Welding and Installations

- Rigging

- Sanitary Welding

Redefining What’s Possible in Mechanical Work

We don’t just weld pipe and set equipment- we build systems that perform at scale and under pressure.

Byers’ mechanical division is constantly pushing the standard forward by refining installation techniques, adopting advanced orbital welding processes, and streamlining how critical systems are installed and maintained. From food-grade to pharma-grade environments, we bring a precision-focused, plant-ready approach to every job.

Precision is the Standard

In mechanical work, quality is essential to safety, sanitation, and uptime.

Our certified welders, millwrights, and fabrication teams follow strict quality protocols from start to finish. Whether it’s sanitary stainless systems or complex equipment lines, we ensure every weld, every bolt, and every alignment meets performance specs before we sign off. We take accountability seriously — because the integrity of your operation depends on it.

Staying Ahead with Real-Time Insights

Whether it’s a rebuild, a retrofit, or a fast-track installation, visibility is everything.

We track field activity daily and use trend data to spot risks early, monitor performance, and keep work on schedule. Our crews document progress in real-time, giving project managers and facility teams the data they need to make smart decisions and stay ahead of costly downtime.