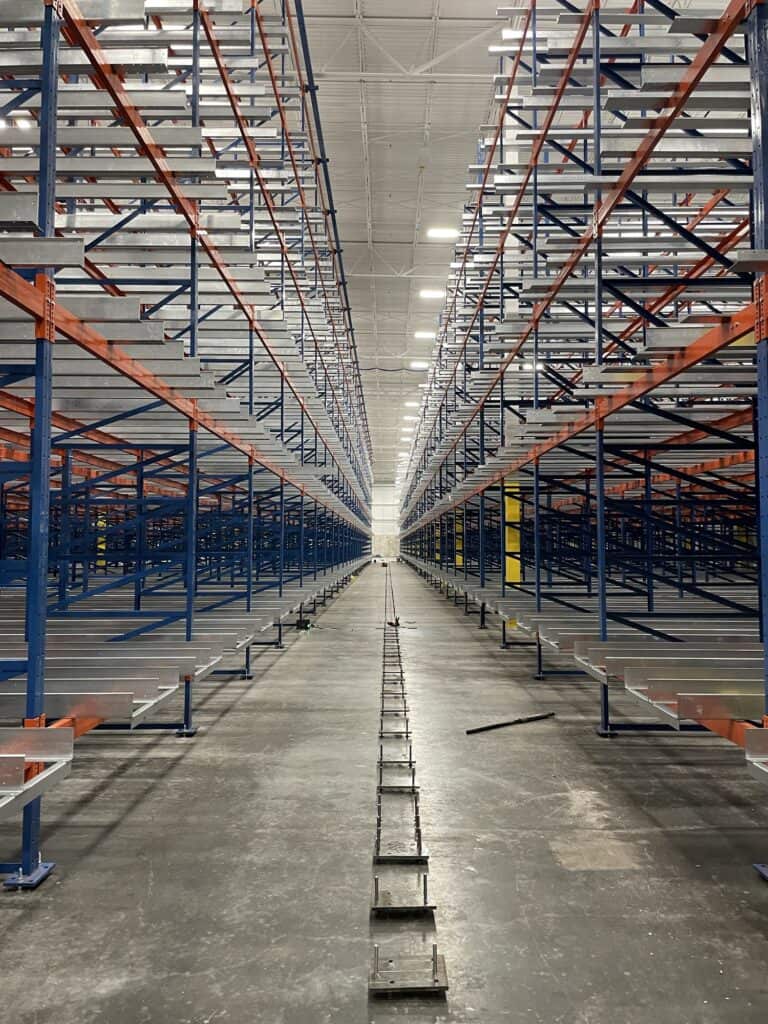

Warehouse Automation SRM Rail Miter Installation – Philadelphia, PA

Byers executed a time-and-materials (NTE) program to install mitered rail for storage/retrieval machines (SRMs), providing equipment, materials, and labor under weekday 10-hour shifts. The plan emphasized safe coordination with adjacent AS/RS workstreams and clean, code-compliant installation practices from offload through final alignment.

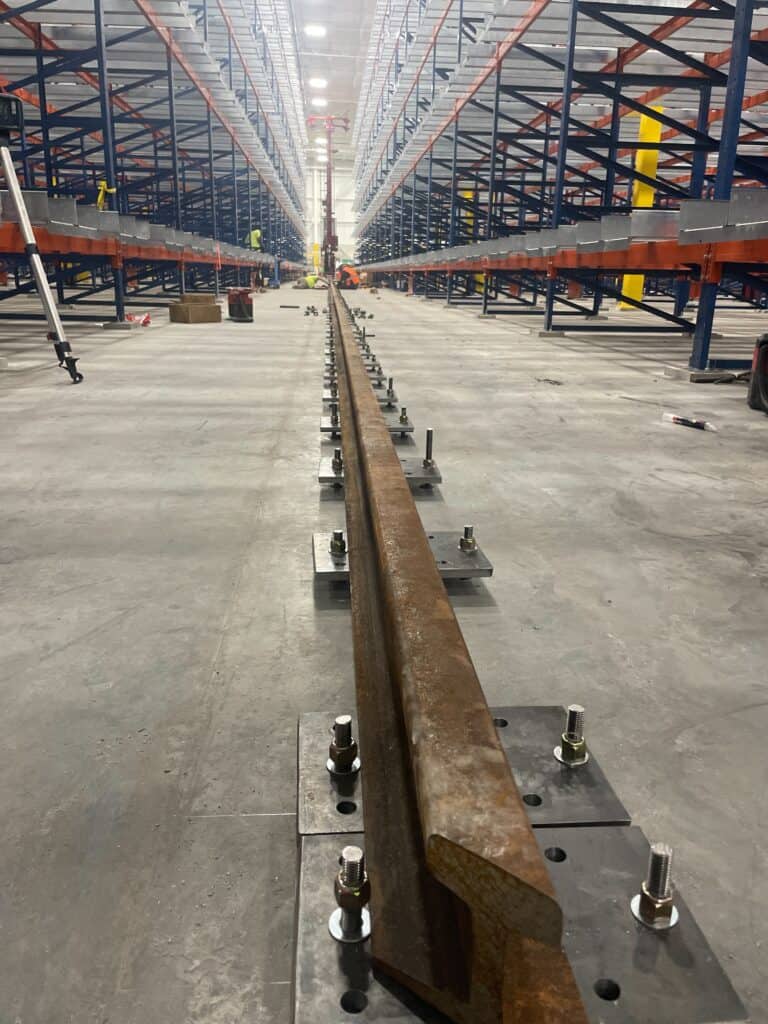

Scope included receiving and inspecting rail components for shipping damage; furnishing rail clips, baseplates, fasteners, threaded rod, and structural anchoring epoxy per the bill of materials; installing rail to the specified statement-of-work tolerances; and disposing of packaging in a vendor-provided dumpster. The base package incorporated factory mitered ends and all required hardware for accurate fit-up.

Execution focused on precise layout, drilling, anchorage, and torque verification to achieve tight tolerances for smooth SRM travel and long-term reliability. Sequenced daytime work windows reduced interference with other trades while enabling efficient QA/QC on rail geometry, fastener integrity, and final tie-ins—delivering a maintainable rail system ready for commissioning.